The second step in producing powder coated galvanized steel is the application of the powder coat to the galvanized part. The AGA offers Preparing HDG Steel for Powder Coating a package that includes an instructional guide booklet and step-by-step DVD video on how to prepare the hot-dip galvanized steel surface for powder coating.

Cable Tray Ladder Perforated Gi Hot Dip Galvanized Cable Tray Cable Tray

Cable Tray Ladder Perforated Gi Hot Dip Galvanized Cable Tray Cable Tray

Yes we can apply a powder coat over galvanized steel to create a high-grade architectural finish.

Preparing hot-dip galvanized steel for painting or powder coating. The preparation for painting and powder coating over a hot-dip galvanized coating as well as the repair of damaged and uncoated areas use SSPC-SP2 as a standard surface preparation procedure. Understanding one of the criteria for measuring the hot dip galvanized coating thickness in terms of SANS 121 ISO 1461. There are documents available that describe methods of preparing surfaces of new and weathered hot-dip galvanized steel for painting.

Authored by Bernardo A. Creating a successful duplex system of powder coating over galvanized steel requires the following seven steps. When paint and galvanized steel are used together the corrosion control provided is superior to either system used alone.

However proper surface preparation is critical for. Industrial Galvanizers has been directly involved in the painting and powder coating of a large number of hot dip galvanized structures and items. Duplex systems such as paint or powder coating over hot-dip galvanized steel have been used for years as a means to enhance corrosion protection.

The galvanized coating protects the base steel supplying cathodic and barrier protection. How to paint galvanized metal. Preparing Hot-Dip Galvanized Steel For Powder Coating DVD.

The painting process is actually very straightforward because the surface of galvanized steel is relatively smooth and consistent. The various parties may desire special handling or require alterations to the design to facilitate the galvanizing process andor the application of paint. The specification ASTM D7803 contains detail on how to prepare the hot-dip galvanized surface for powder coating.

A duplex system is simply painting or powder coating steel that has been hot-dip galvanized after fabrication. There are four recognised methods of surface pre-treatment that produce a sound substrate for a paint coating. If hot-dip galvanized steel is going to be painted communication between the fabricator specifier painter and galvanizer is vital before galvanizing.

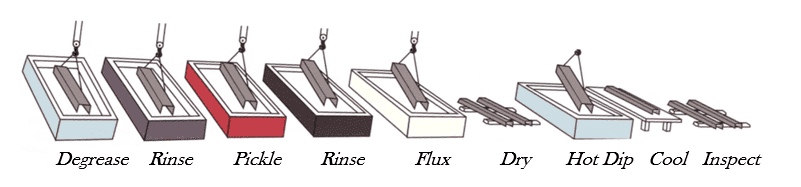

There are well established quality assurance procedures for the painting of hot dip galvanized components in a controlled. Powder coating over hot-dip galvanized steel provides the ownerspecifier with effective corrosion protection while still allowing the. The preparation of the hot dip galvanized steel for powder coating or painting involves two steps which are as follows.

Similar to painting over black steel surface preparation is critical when painting or powder coating over the zinc coating of hot-dip galvanized steel. Even though this standard is specific to powder coating of galvanized steel it contains the same cleaning and preparation techniques for the surfaces coated with liquid. In addition to SSPC-SP 16 referenced earlier ASTM International has published Standard Practice D6386-10 Standard Practice for Preparation of Zinc Hot-Dip Galvanized Coated Iron and Steel Product and.

The cleaning is done to remove the dirt from the surface. There are many instances where hot dip galvanized coatings need to be painted. Let the primer dry completely which should take anywhere from 2-6 hours so your paint will stick properly.

T wash etch. Preparing hot dip galvanized steel for painting a duplex system. Once the primer has dried apply your first coat of paint with a brush or roller.

Example of a completed duplex system. This combination provides exceptional resistance to the elements but galvanized products require surface preparation to ensure a quality and lasting coat. ASTM D7803 Standard Practice for Preparation of Zinc Hot-Dip Galvanized Coated Iron and Steel Product and Hardware Surfaces for Powder Coating addresses powder coating.

To paint galvanized steel start by applying a latex-based primer evenly across the surface to stop the paint from soaking into it. An even layer of polyester powder coating is applied to the recently galvanized steel and cured in a stove at 180 C. In fact roughly 69 of steel is recycled in North America each year.

Preparing the hot-dip galvanized steel surface for painting or powder coating. Preparation of galvanized steel before painting. Powder coatings must be applied within 12 hours of the galvanizing process.

Powder coating on Hot Dip Galvanized HDG steel or also known as creating duplex system is combining the superior protection of galvanized steel with the additional benefits of another corrosion protection system such as powder coating or paint to extend the corrosion protection of the piece even further. Download Citation Preparing hot-dip galvanized steel surfaces for painting or powder coating. Painting galvanised metal is very easy as long as the right steps are carried out.

A primer When paint and galvanized steel are used together the corrosion control provided is. The following is a quick introduction for the process. The specifications for preparing hot-dip galvanized steel for paint and powder coating ASTM D6386 and D7803 respectively list hand tool cleaning as an acceptable method for smoothing the surface and removing zinc high spots of newly galvanized and partially weathered coatings.

However its important to do this task carefully because highly acidic or even basic cleaning sometimes scrapes off the zinc from the surface. Galvanized steel is a great material to use for a variety of tools products and projects and its environmentally friendly. Before applying powder coating to any galvanized steel products we recommend blasting and.

Galvanizers Page 5 Of 11 Supplier Consultant Of Hot Dip Galvanizing Plants In India

Performance Of Hot Dip Galvanized American Galvanizers Association

Performance Of Hot Dip Galvanized American Galvanizers Association

.jpg) Galvanized Steel Causes And Defects In Galvanized Coatings

Galvanized Steel Causes And Defects In Galvanized Coatings

Just Spray S Guide To Powder Coating Galvanised Steel

Just Spray S Guide To Powder Coating Galvanised Steel

Hot Dip Galvanizing Archives Page 3 Of 5 Galvanizers

Powder Coating Hot Dip Galvanized Steel Kta Universitykta Tator

Powder Coating Hot Dip Galvanized Steel Kta Universitykta Tator

Hdgasa Hot Dip Galvanizers Association Of Southern Africa

The Painting Of Hot Dip Galvanized Steel Hdgasa

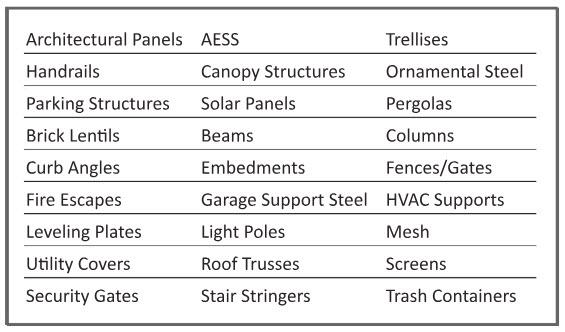

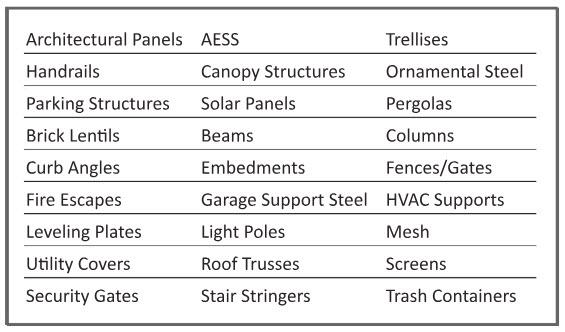

Hot Dip Galvanizing For Buildings And Architecture Construction Specifier

Hot Dip Galvanizing For Buildings And Architecture Construction Specifier

Surface Preparation To Ensure Accurate Hot Dip Galvanizing Tanya Galvanizers

Hot Dip Galvanizing Protecting Steel For Generations Youtube

Hot Dip Galvanizing Protecting Steel For Generations Youtube

Duncan Galvanizing Blog Hot Dip Galvanizing

Duncan Galvanizing Blog Hot Dip Galvanizing

Hot Dip Galvanized Steel American Galvanizers Association

Hot Dip Galvanized Steel American Galvanizers Association

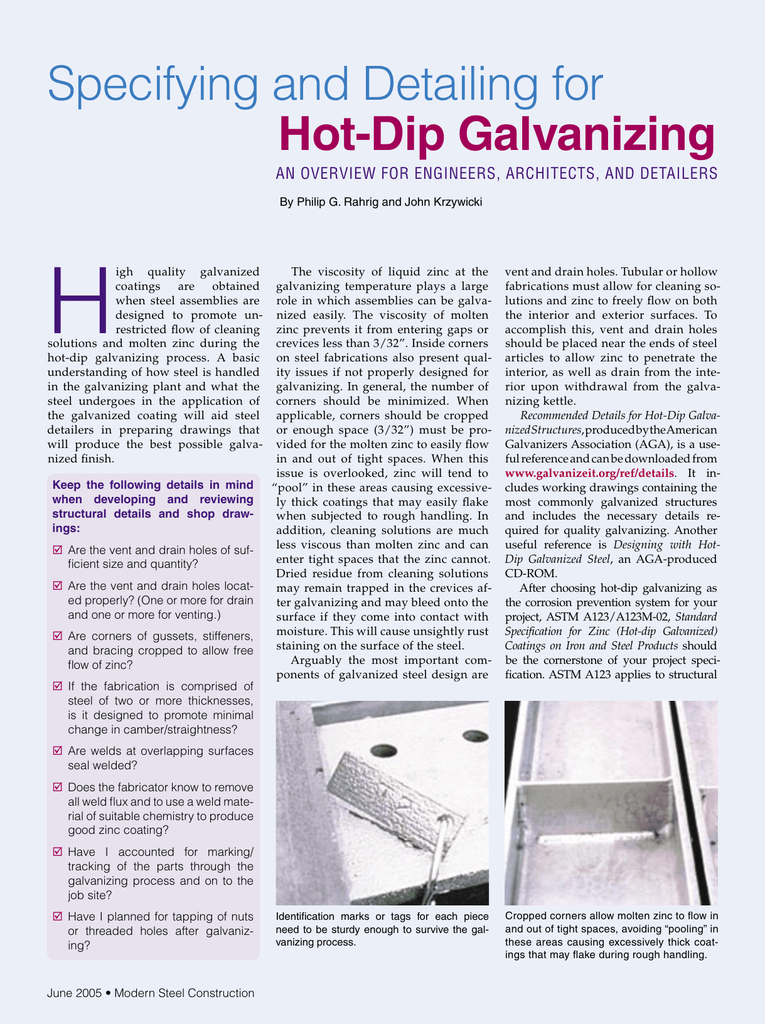

Specifying And Detailing For Hot Dip Galvanizing

Specifying And Detailing For Hot Dip Galvanizing

How To Prepare Hot Dip Galvanized Steel For Powder Coating

Preparing Hot Dip Galvanized Steel American Galvanizers Association

Preparing Hot Dip Galvanized Steel American Galvanizers Association

Paint Galvanised Steel Galco Hot Dip Galvanising

Paint Galvanised Steel Galco Hot Dip Galvanising