292mm 11 12 weight. Pull your tape before the paint sets.

Fibreglass Frp Split Mould Making Guide Carbon Fibre Airbox Pt 2 Carbon Fiber Mold Making Fiberglass

Fibreglass Frp Split Mould Making Guide Carbon Fibre Airbox Pt 2 Carbon Fiber Mold Making Fiberglass

Macarons straight from the mould These are the macarons put together to ensure that they fit together well.

Painting fibreglass straight from the mould. Finally for painting detail or spot colors I simply work straight from the tube. Unscrew the cap wet the brush with just enough water to lubricate. Styrene is the solvent that makes that resin a liquid.

I agree with the other people who have suggested semi-gloss or high gloss paint finish. Please look closely at the pictures part number is a reference only and not intended to imply this is that part. Measures 2850 in length by 3625 wide with an arc length of 3175 - includes inside and outside pieces.

Wednesday 7th May 2008. Never use paint straight from the original can. GRP and fibreglass composite technology has come a long way since the Jensen Interceptor and Reliant Robin first hit our streets in the early 70s.

Once all the painting is complete the macarons shells will be bonded to either side of the cream. Hi Guys had a bit of a search and not found. Wall under a layer of paint and fiberglass still breathing so it does not accumulate moisture which leads to the development of mold.

They have used fibreglass for the 32m domes and suggested that I used the mould that they had constructed to build the 12 fibreglass sections required for the complete dome. The two outer shells will be painted separately to the cream. Ready for post production painting.

Stir the paint and add more gum arabic until you recover a smooth mixture. It has to be trimmed and painted black on the inside. In the 25 years Ive been doing fiberglass work Ive never had to thin resin except for one type of application.

Im classing these as reject to make them as cheep as possible straight from the mould means there will by flashing to remove and minor reshapingcorrecting to be done after some clean up its an r2d2 kit life size and screen accurate all parts are included including the periscope. Alternatively components can be supplied in a finish ready to take your primer and top coat paint. May require sandingfinish work before being ready for paint as our fiberglass is pulled straight from the mold and may have visible casting marks.

This is a custom order it will take time to make and ship. The whole process needs a lot of patience but it can be done. The wood in these flexible constructions such as lapstrake clinker-built or carvel-planked will move as the moisture content varies leading to cracking.

Roadster - bare right hand fibreglass side panel. For bare wood you may want to stay with a single-part paint system. Fibreglass Moulds forsales grouped as our Small truck Aero roof products 7 main universal aero roof moulds with a multiple of various wings for many ranges of small and medium trucks Isuzu Hino Iveco UD Freightliner mitsubitshi Fuso MAN ford kenworth Aero roof to suit starting from 550 each mould message with what you are interested in.

A small tin of body filler may be needed to complete before painting. Using watercolor straight from the tube for spot color. Here we see the section straight from the mould.

Straight from the. The green colour comes from the particular resin used. The cost of such paints as compared to water-based paint - much more expensive.

On bare substrates such as fiberglass aluminum steel and epoxy you can use any of the Interlux paint systems. Oil based would be OK. As produced for our new ABM 765 GP2 bike these fairings are now available for sale to the general public.

Use a smaller temporary container and pour out only enough paint to keep you busy before it starts to dry out. You can buy it straight from the fiberglass supply shop. Parts come straight from the mould in a charcoal grey.

GRPlite take pride in offering a hand crafted finish straight from the mould to the car eliminating the need for post production painting thus giving a more durable finish for the specialist racing customer. Using les-sons learned on the small wheel Exit also developed the mold for its larger straight-spoked wheel. Available in either fibre Glass or Carbon Fibre they may be ordered as a complete kit or as individual parts.

Gel coat ready to paint or use material. No more than 5 would be my guess try it and see. The kit includes the following items.

This painting process is easy to use because there is no need for intermediate processes such as priming and pre-painting. Painting fibreglass straight from the mould. Straight from the mould will need drilling trimming and filing to fit.

If you want to thin polyester resin use styrene. A prototype closed mold which splits centrally in the plane of the wheel was then made from the model using gel coat and fiberglass. Keep stirring what you poured out and keep the lid on your main paint can tight.

Right these are straight from the mould. The company that makes it Flood Australia also has a paint additive VC175 that you can treat the paint with to prevent mould occuring. For fiberglass acrylic paint different popular because of the safety of use lack of odor and quick drying.

Black gel coat is ok but painting would improve. Or manufactured with a durable colour finish straight from the mould for the seriously weight conscious specialist racing customer. 1x blank fiberglass centre console - single this listing is for a blank console pulled straight from the mould - with no fittings or accessories supplied custom fit to each boat manufactured out of fiberglass finish sand-able grey gel coat finish - this item will require sanding and painting before fitting to your boat height.

In combination with automated manufacturing this process is ideally suited to efficient series production of premium quality parts for use in the automotive industry explains Nicolas Beyl head of the Reaction Process Machinery division at KraussMaffei. Interstate fibreglass side panel black right hand. Parts are thick gelcoat and resin hollow for wiring etc.

No fitted brackets no holes drilled black gel finish is ok paint would be recommended sturdy but work.

A Car Body Mold Building Composite Parts Epoxyworks

A Car Body Mold Building Composite Parts Epoxyworks

How To Mold Fiberglass Wing Step By Step Youtube

How To Mold Fiberglass Wing Step By Step Youtube

How To Build A Fiberglass Mold Building A Mold For A Cx500 Motorcycle Side Cover Youtube

How To Build A Fiberglass Mold Building A Mold For A Cx500 Motorcycle Side Cover Youtube

Making A New Fiberglass Hatch From A Mold Youtube

Making A New Fiberglass Hatch From A Mold Youtube

Fibreglass Mould Making Fibreglass Sydney

Fibreglass Mould Making Fibreglass Sydney

Fiberglass Mould For Planter Smisetti Demoulding Youtube

Fiberglass Mould For Planter Smisetti Demoulding Youtube

Fiberglass Mold Making An Introduction To Plugs

![]() Taking Fibreglass Moulds Of Vehicle Panels Video Tutorial Easy Composites

Taking Fibreglass Moulds Of Vehicle Panels Video Tutorial Easy Composites

How To Mold Fiberglass Fiberglass Mold Fiberglass Boat Building

How To Mold Fiberglass Fiberglass Mold Fiberglass Boat Building

Fibreglass Vacuum Moulding Fiberglass Mold Fiberglass Fiberglass Resin

Fibreglass Vacuum Moulding Fiberglass Mold Fiberglass Fiberglass Resin

How To Make A Fibreglass Car Wing Mould Carbon Fibre Copy Carbon Fiber Fiberglass Auto Body

How To Make A Fibreglass Car Wing Mould Carbon Fibre Copy Carbon Fiber Fiberglass Auto Body

Making Glassfiber Moulds East Coast Fibreglass Supplies

Making Glassfiber Moulds East Coast Fibreglass Supplies

Fiberglass Plugs Patterns Molds Accurate Pattern

Fiberglass Plugs Patterns Molds Accurate Pattern

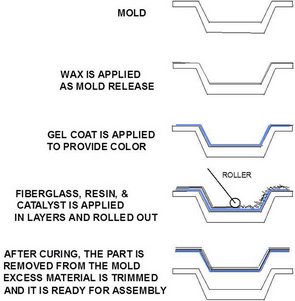

How To Mold A Fiberglass Part Instructions Cst The Composites Store Inc

How To Mold A Fiberglass Part Instructions Cst The Composites Store Inc